The welding machines or plasma cnc machine, generally are the CNC plasma table and plasma cutter, this is the true workstations of mechanized plasma cutting, the plasma table cost is out of the budget and the needs of a hobbyist or home user, but represent a recommendable acquisition in larger workshops and industries. Buy the best affordable cnc plasma cutting table systems we have for sale in our web on the follow links.

Contents

Buy the best plasma table for sale of 2019

See the best plasma table for sale in amazon in a cheap price.

Buy the Best plasma cutter for sale of 2019

Buy the best plasma cutting table for sale on a cheap price in amazon on offer at the best price.

What is plasma?

Matter is present in everything we know, inside and outside this planet. However, matter is in three different states: Solid, Liquid and Gaseous. The best way to understand this concept is to imagine it with respect to water. What makes that, in the case of water, we can have three states of matter, is the level of temperature to which it is subjected. If the temperature is extremely low, the condition will be solid (ice). If the temperature is ambient, the water will be liquid and if we raise the temperature level considerably and continuously, we will obtain a gas.

However, when we obtain a liquid in a gaseous state, it is possible to increase the temperature further, and obtain an electrically conductive gas. The ionization of gases generates the creation of positive ions and free electrons. When this occurs, the gas becomes a current conductor, reaching what some consider a fourth state of matter.

What is plasma cutting technology?

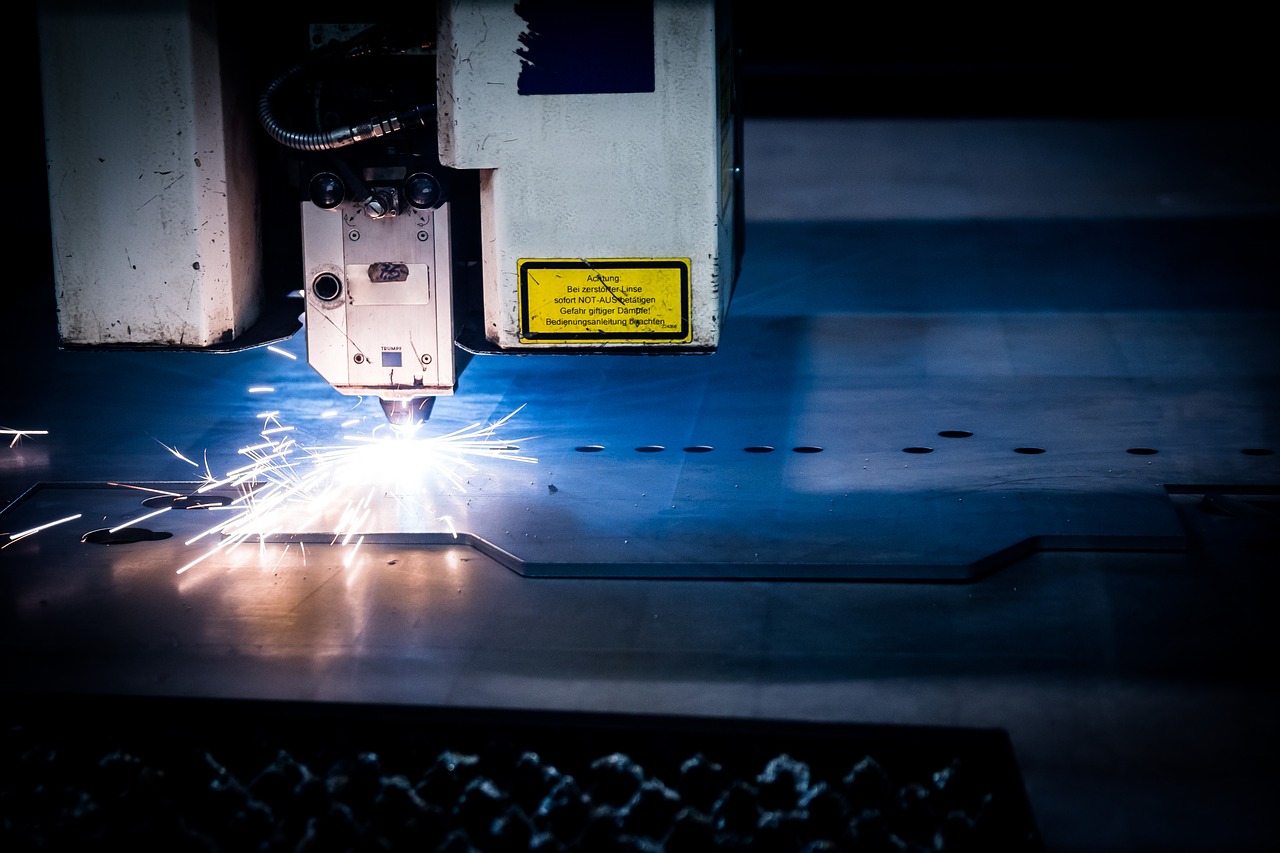

The conductivity of the current and the high temperature is such that, by adapting certain tools, cnc plasma cutting table machines are built by means of a beam directed on a metal surface.

Plasma cutting is a process that uses a nozzle, with an orifice for the circulation of ionized gas at high temperatures, so that a beam is obtained that can be used to cut sections of metals such as carbon steel, steel stainless, aluminum and other electrically conductive metals. Through the use of this technique, the plasma arc melts the metal, and the gas removes the molten material.

Plasma cutter for cnc table have evolved since their appearance almost seventy years ago. Today, they even incorporate computer numerical control systems, popularly known as CNC. These types small cnc plasma table for sale are also available in our online store.

What is a cnc plasma table?

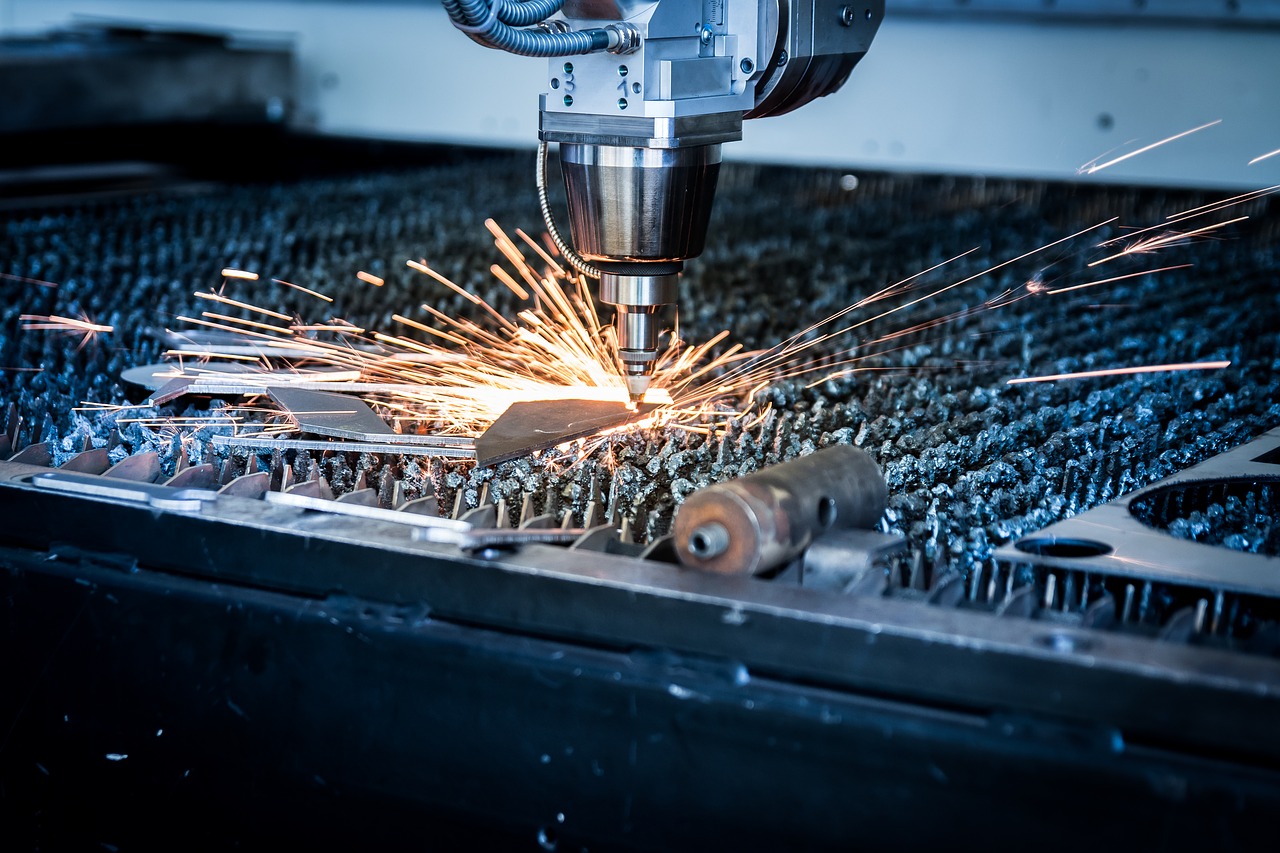

Cnc plasma cutter definition? A cnc plasma table or welding plasma table is a computer-controlled machine to which a cutting tool can be mounted, in the case of our equipment it is a plasma torch and optionally flame cutting. The acronym CNC means computer numerical control. CNC pantographs equipped with a plasma torch can make metal cuts of any type of geometric figure that you have previously drawn on your computer.

Why Buy a Electricpowerplant a CNC plasma table for sale in our web?

A CNC plasma table for plasma cutting produces consistent high quality work and improves factory productivity. Unlike cutting parts manually, a cnc plasma table for plasma cutting can cut with the same quality and precision whether one piece or several hundred pieces, they will always remain identical.

A CNC pantograph for plasma cutting BOYSER will automate and increase your production, while reducing your operating costs. In short, they will reduce costs and increase your profits.

In principle, they should know that cnc plasma table are called that way because of the way the machine is and the way it performs cutting or engraving, which can be plasma or flame cutting. In this sense, there are different types of pantographs, which differ depending on the technology they use to work, as well as the sector in which they are implemented.

- Manual CNC plasma table, which over time have been replaced by more modern and computerized versions, such as infographics, are no longer used to make cuts, but only for printing.

- The cnc plasma table infographic, meanwhile, work on flat surfaces and make cuts with steel blades, laser or diamond blades, which makes them very effective in their work and that is why they are favorites.

- 3D CNC plasma table have greater reproducibility and workload thanks to their computer development.

- The CNC plasma table are operated with commands programmed in a storage medium and are very effective, so they are currently the most used and, in addition, those that implement the most technology in their operation.

How does a cnc plasma table work?

It is a machine that, using computer software, is capable of transferring a cutting pattern to a sheet of metallic material, using the plasma cutting system. To carry out this work, it consists of a large support table where the material plates are placed (horizontally so that the cut is carried out properly). Meanwhile, a moving head, performs perpendicular cuts or drafts on the support table. Plasma cutting is a technology developed to cut steel and other metals using a plasma torch. A CNC plasma table is useful for cutting any conductive and non-ferrous metal material, especially structural steel, stainless steel, aluminum, copper and brass.

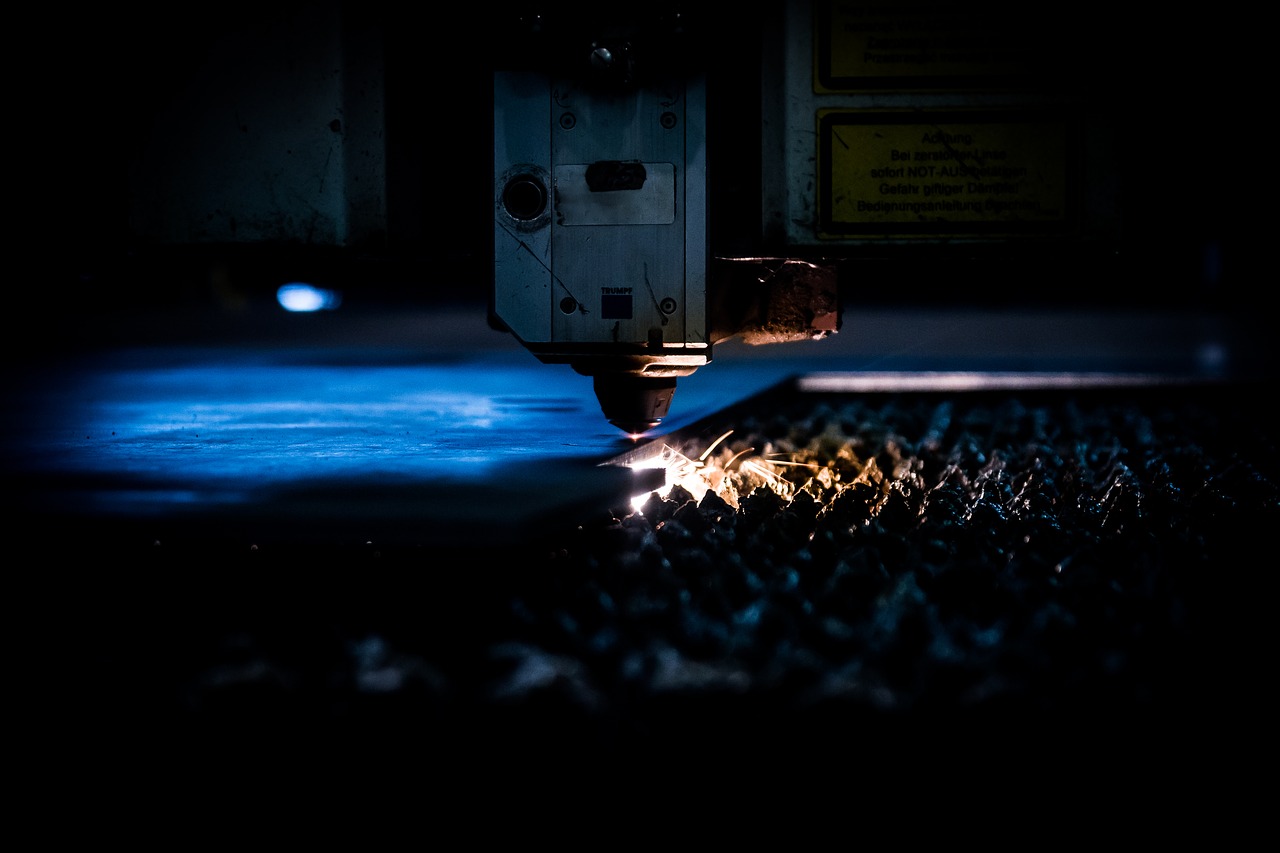

The technique of this machine consists in the application of heat in order to raise the temperature of the material to be cut in a focused manner, so that the material can reach 30 thousand degrees Celsius, causing the gas used by the Machine is ionized turning it into plasma with electric conduction. By means of the formation of an extremely small electric arc, with a large amount of energy concentrated in the torch nozzle section, highly compact heat is produced in the cutting area, which is why the CNC cutting machinery It is very effective and widely used.

This is how the cut made by the plasma cutters occurs when the heated gas is ionized and comes into contact with the surface to be cut, penetrating and melting the material, with a subsequent release of the excess metal. Because the plasma has the characteristic of being a conductor of electricity, the plasma cutting process is continuous, as long as there is energy in the electrode and the plasma is kept in contact with the material to be cut.

It is important that they know that the plasma cut emits ultraviolet radiation, so that eye protection such as dark glasses, adequate clothing and ventilation is required and avoid the presence of flammable materials in the surroundings. It is important to note that these machines, as well as the electric welding machines that we also offer in Welding Technologies, have interesting benefits, which we will list below so that they better understand why it is a widely used machine.

Advantages of cnc plasma table

- Improves accuracy: Since CNC machines operate from computer programs, they offer greater accuracy compared to manually operated mechanical machines.

- Safety: The operation of CNC machines is executed through computer programs, which means that the worker will not be in direct contact or exposed to the cutting tools, which can be translated as a worker free of danger and safe in Your work area.

- Waste reduction: CNC machinery helps reduce metal waste, as it is designed with leftover management systems resulting from machining or cutting processes, which accumulates in workshops without having a particular use. Therefore, these systems provide an optimal solution for working with metals in different ways, as they improve the management of cuts to have the best use of materials.

- Reduction of worker involvement: With the incorporation of CNC machinery, companies can perform the most complex operations in a few minutes, without the intervention of a machine operator or an engineer. This considerably reduces payroll expenses, which means that the company can make higher profits; In addition, it will reduce the chances of errors.

- Execution of complex cuts: The machinery that uses CNC cutting table technology can execute complex processes that would require great efforts and time in the case of being made by hand. All you have to do is configure the machine and integrate the programs.

What is a cnc plasma cutter?

Like the MMA or the TIG station, this tool needs an inverter (device that transforms alternating current into direct current) to produce the electric arc that allows this ionization that will generate a temperature rise of about 18000 º C. Air production requires an attached or integrated compressor. The cutting equipment is complemented with a sophisticated torch, as well as with a dough clamp, which is fixed on the piece or plate to be cut.

Why buy a CNC Plasma cutter?

Choose the cnc plasma cutter systems depending on the project to be carried out. The criteria of use in a well defined environment serve to determine your choice. The budget is undoubtedly decisive, but keep in mind that excellent work can be done with a portable, compact machine at a very good price.

Portable plasma cutters with integrated compressor are the most effective solution for newbies. Its weight, its light size and its technical characteristics make it a good choice for anyone who wants to cut plates or profiles in a precise way. Because the Inverter technology facilitates the automatic adjustment of the current frequency, the compact plasma cutters are undoubtedly the best option.

How does a cnc plasma cutter work?

It is important to know that plasma produces many gases. It should be used in a ventilated environment, outdoors and adequately protecting the respiratory tract.

After connecting the plasma cutter and putting the dough clip on the metal plate to be cut, the torch is approached and the trigger is pressed to activate the remote start (thanks to the high frequency) and start the phase of metal melting The technique is to keep the torch at a suitable distance for a regular and clean cut. There are many torch accessories that facilitate cutting:

- a skate that preserves the distance for those who tend to move away or approach;

- a compass for cutting discs;

- a guide rule, etc.

The cut usually has a clean and less precise face. It must be taken into account for the completion of the work, giving importance to the side of the surplus.

Advantages of cnc plasma cutter?

The main advantage of this system lies in its reduced risk of deformation due to the heat compaction of the cutting area. The economy of the applicable gases is also valuable, since a priori anyone is viable, although it is true that it should not attack the electrode or the piece. You can buy a inexpensive plasma table in a affordable price in amazon, you can see many cheap cnc plasma cutting systems for sale in offer.

See others Plasma Cutter products

See other plasma table for sale and plasma cutter in the follow link.